Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Jiema

Material: Carbon steel, Stainless steel

Usage: Cooling, Heating

Packaging: Plywood box

Productivity: 1000 pcs per month

Transportation: Ocean,Land,Air,Express

Place of Origin: Guangzhou, China

Supply Ability: 1000 pcs per month

Certificate: ISO 9001:2015 CE

HS Code: 8419500090

Port: Guangzhou

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW,DDU,Express Delivery

Waste Heat Recovery System(WHRS), or Wastewater Heat Recovery System(WWHRS), becomes a real sensation as the world is currently in a campaign of advocating environmental protection. JIEMA responds to the call and had already helped millions of Companies at home to perfect their Waste Heat Recovery Line. And now, we are ready to assist a million more.

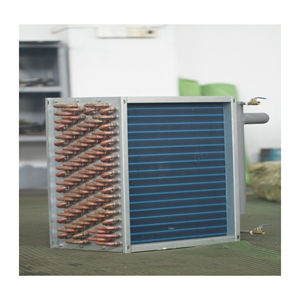

Jiema Fin Tube Heat Exchanger in WHRS Power Plant is characterized by compact structure, nice appearance, easy installation and management and high durability. It is applicable to the heating based on centralized air supply and local heating and other purposes as well.

1. Before installation, inspect whether the heater is intact and screw off the pipe clamps and the plugs.

2. Connecting the connection tubes (water tube and steam tube) with the same size as connectors of the heater’s inlet pipe and outlet pipe. Do not support the heater with the connection tubes.

3. Equip a corresponding heat medium pipe system for our Fin Tube Heat Exchanger according to the architectural design. Gate valves should be installed on the steam pipe (or the hot water pipe) and the return water pipe; a condensed water drainage device should be installed on the condensate water pipe. When multiple air heaters are used at the same time, particularly when air is in a serial connection state in the air flow, it would be best that each can control its air inlet device, air outlet device and return water pipe device.

4. When the air inlet pipe of the Finned tube air heat exchanger is in direct connection with an outdoor place, a blocking device should be arranged at the air inlet to avoid damage of the air heater due to freezing when it is not in service.

2) Install a steam trap at the end where the return water connection tube is and make sure its displacement is larger than three to four times of the condensate water volume of the air heater.

3) Feed steam about ten minutes before the fan is started to preheat the Fin Tube Heat Exchanger to avoid impact on the equipment by a lot of condense water as a result of sudden entry of steam into the cold air heater.

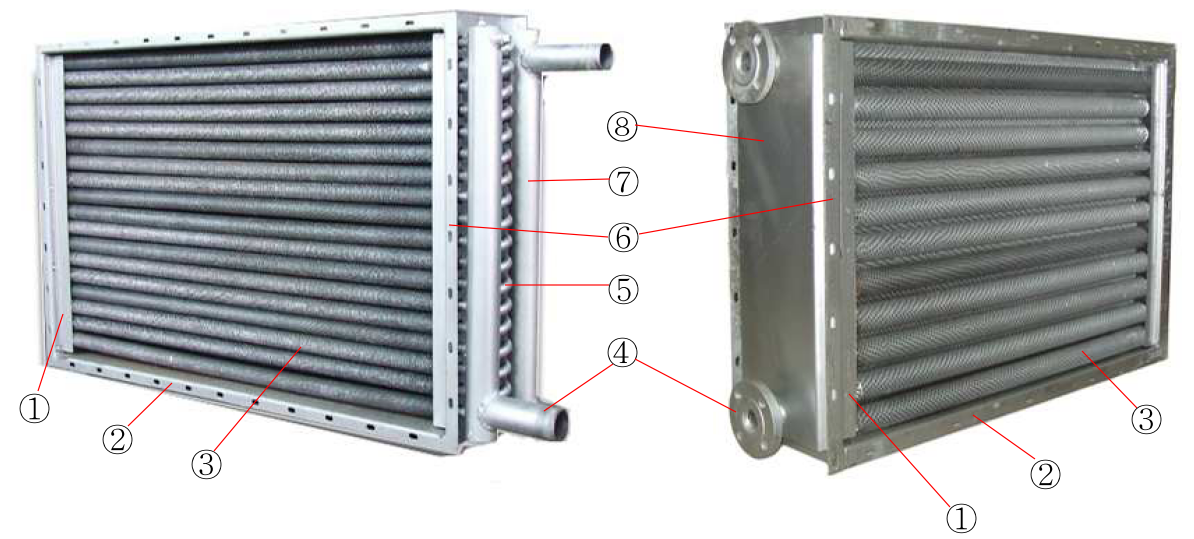

As in the figure below, the Fin Tube Heat Exchanger in WHRS Power Plant, also in WWHRS or Orc Heat Recovery, comprises two wind boards, two connecting plates, two heat exchange tubes, two connections, an elbow, two tube plates, a header pipe and a header tank.

① Window board ② Connecting plate ③ Heat transfer tube

④ Connection(Flange&Screw Thread) ⑤ Elbow ⑥ Tube plate ⑦ Header pipe ⑧ Header tank

1. What is the advantages of Fin Tube Heat Exchanger?

a.High heat transfer performance and low contact thermal resistance;

b. The contact area between the fin and the tube is large,and the joint is tight and reliable;

c. Good corrosion resistance and stable long-term service performance;

d.The fin has good rigidity and is not easy to deform.

2. What are the operating conditions of Fin Tube Heat Exchanger as in WHRS Power Plant, WWHRS or Orc Heat Recovery?

Fin Tube Heat Exchanger is best suitable for non-corrosive fluids with high purity and less scale formation.

Product Categories : Air Heat Exchanger > Finned Tube Heat Exchanger

Home > Products > Air Heat Exchanger > Finned Tube Heat Exchanger > Fin Tube Heat Exchanger in WHRS Power Plant

Send Inquiry

Ms. Abby

Tel:+86-020-82453507

Fax:

Mobile Phone:+8613662249479

Email:jmheatexchanger@163.com

Address:No.73, Bigang Road, Nangang Street, Huangpu District, , Guangzhou, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.