Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

2020-05-11

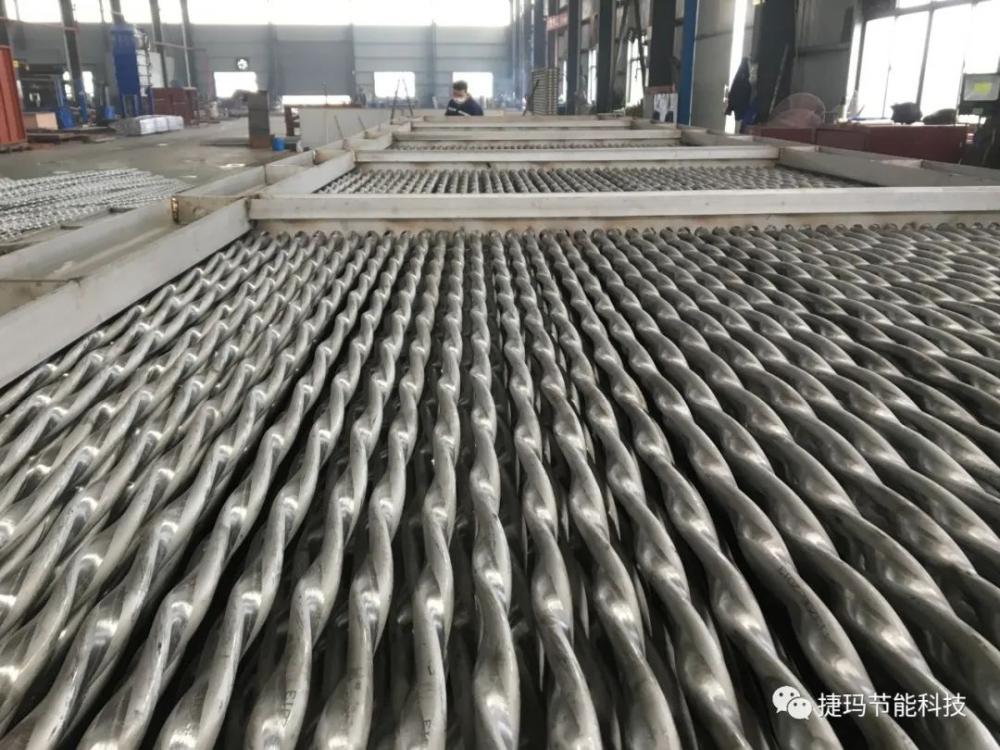

Sintering refers to heating iron ore powder or powder compact to a temperature lower than the melting point so to produce a certain amount of liquid phase, which interacts with un-melted ore particles and forms a bonded and sintered body with higher strength, thereby obtaining products required. However, flue gas treatment of most sintering machines remains a concern where a great amount of water vapor and heat is wasted and emitted to the atmosphere.

Eventually, condensed flue gas is about 42°C-45°C. In order to achieve the purpose of eliminating whitening, the flue gas needs to be reheated. The reheating uses the process circulating water to achieve no whitening throughout the year. At the same time, the energy consumption of subsequent installation of denitrification systems is reduced through waste heat recovery and utilization.

Share to:

Send Inquiry

Ms. Abby

Tel:+86-020-82453507

Fax:

Mobile Phone:+8613662249479

Email:jmheatexchanger@163.com

Address:No.73, Bigang Road, Nangang Street, Huangpu District, , Guangzhou, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.