Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Jiema

Packaging: Plywood box

Productivity: 1000 pcs per month

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 1000 pcs per month

Certificate: ISO 9001:2015 CE

HS Code: 8419500090

Port: Guangzhou

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,Express Delivery,EXW,DDU

Cooking oil, special and indispensable ingredients of our daily diet, requires strict procedure during its production, among which JIEMA PHE Condenser for Milk or Vegetable Oil Cooling earns its name as the most beneficial oil cooler.

To find a proper oil cooler, gaskets made of EPDM are to be avoided as it has poor oil resistance. Having said that, JIEMA PHE Condenser for Milk or Vegetable Oil Cooling would be a perfect choice since we apply rubbers with strong oil resistance such as NBR and Fluorine Rubber.

PHE Condenser sheet: SUS304, SUS316L, SMO254, Titanium, Nickel, Hastelloy Alloy

Frame: Carbon steel, stainless steel, coated stainless steelGasket seal: NBR, H-NBR, EPDM, food pad, fluorine rubber, silicon rubber

Clamping bolt: Galvanized carbon steel, stainless steel

Interface: Rubber, carbon steel, stainless steel

Guide bar: Galvanized carbon steel, stainless steel

| Material Description of Phe Gasket | Code | Applicable Temperature (ºC) | Anti-corrosive Performance and Applicable Occasions |

| NBR | N | -20~110 | Hot air, water, non-polar oil, mineral oil, lubricant and silicone oil, etc. |

| EPDM | E | -50~150 | Vapor, polar chemical medium, alcohol, weak acid, weak alkali and oxidizing agent, etc. |

| Fluorine Rubber | F | 0~180 | Inorganic acid, alkali, mineral oil and |

| Silicon Rubber | Q | -65~230 | Resistant to cold current and dry hot |

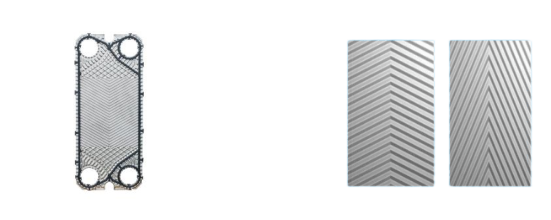

The corrugation of the sheet in Plate Heat Exchanger for Refrigeration can make fluids generate turbulent flow with minor Reynolds number; its heat transfer coefficient is 3-5 times as large as that of shell-and-tube heat exchanger, reaching 7,000W/m2K at the most.

PHE Condenser features compact structure. The heat-exchanging area per unit volume is 2-5 times as large as that of shell-and-tube heat exchanger; the floor area occupied by Plate Heat Exchanger for Refrigeration is approximately one fifth to one tenth of the area occupied by shell-and-tube heat exchanger, given that the same heat exchange task is fulfilled by them.

As for water-water heat exchange, the lowest temperature difference at the end can be lower than 1℃, which is extremely beneficial to the recovery of low-temperature heat energy.

FAQ

FAQ

1. How long can we deliver a PHE Condenser?

15-40days after payment.

2. Can Plate Heat Exchanger in Refrigeration get dirty?

Yes. As the operation proceeds, not only dust accumulates on the surface of plate heat exchanger, but also scale might forms at the wall. But don't panic just yet! PHE Condenser only need a thorough cleaning every two or three years depending on the real operating situtations. Unusual signals such as sudden increase of power consumption, longer time of heat transfer, and poor cooling water quality from the outlet could be a call for you to conduct a cleansing. Also feel free to ask us any related questions!

Product Categories : Plate Heat Exchanger > Plate And Frame Heat Exchanger

Home > Products > Plate Heat Exchanger > Plate And Frame Heat Exchanger > PHE Condenser for Milk or Vegetable Oil Cooling

Send Inquiry

Ms. Abby

Tel:+86-020-82453507

Fax:

Mobile Phone:+8613662249479

Email:jmheatexchanger@163.com

Address:No.73, Bigang Road, Nangang Street, Huangpu District, , Guangzhou, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.