Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: JIEMA

Material: ss 304

Weight: need to be confirm

Design Pressure: 1 MPa

Test Pressure: 1 MPa

Packaging: Plywood

Productivity: 10000000 sets

Transportation: Ocean,Land,Air,Express

Place of Origin: Guangzhou, China

Supply Ability: 1000000 sets

Certificate: ISO/CE

Port: Guangzhou

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

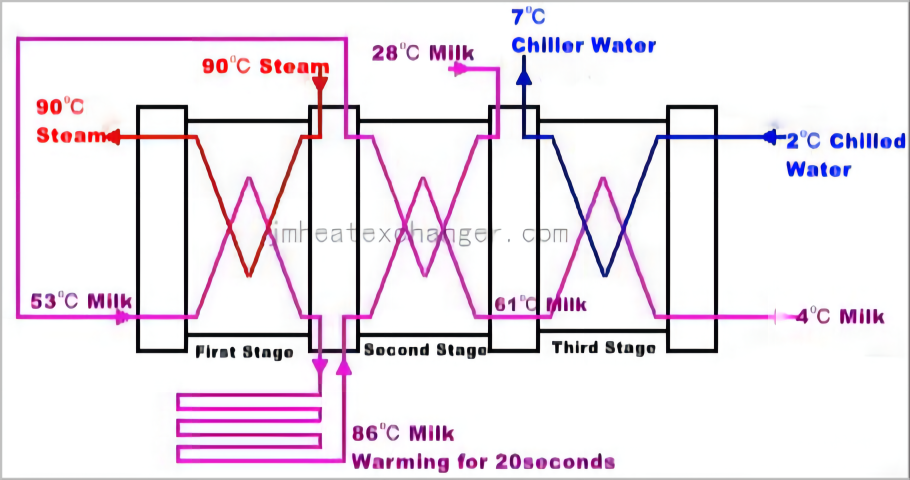

Alcohol lees centrifugal liquid is discharged from the bottom of the crude distillation tower after separation of the clear liquid, the temperature is 80 ~ 82 ℃, due to the high temperature, activation enzyme vitality loss is large. Therefore, it must be cooled by Plate Heat Exchanger first.

Liquefied mash secondary steam volume is large, the use of plate heat exchanger will be this part of the heat recovery and used to heat the process water, evaporation section of the secondary steam condensate and lees centrifugal liquid, etc., can effectively save energy.

Both the recovery of waste heat and the saveing of water. From the production operation of the actual measurement, plate heat exchanger resistance is lower than the original Shell And Tube Heat Exchanger.

The use of plate heat exchanger cooling water consumption is only 1 / 3 of the cooling water consumption of the serpentine cooling heat exchanger, and the effect is significant.

Production of anhydrous alcohol manufacturers of finished alcohol cooling is appropriate to use the plate type stainless steel heat exchanger.

Product Categories : Plate Heat Exchanger > Plate And Frame Heat Exchanger

Home > Products > Plate Heat Exchanger > Plate And Frame Heat Exchanger > Plate Heat Exchanger in Alcohol Industry

Send Inquiry

Ms. Abby

Tel:+86-020-82453507

Fax:

Mobile Phone:+8613662249479

Email:jmheatexchanger@163.com

Address:No.73, Bigang Road, Nangang Street, Huangpu District, , Guangzhou, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.