Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Jiema

Material: Carbon steel, Stainless steel

Usage: Cooling, Heating

Packaging: Plywood box

Productivity: 1000 pcs per month

Transportation: Ocean,Land,Air,Express

Place of Origin: Guangzhou, China

Supply Ability: 1000 pcs per month

Certificate: ISO 9001:2015 CE

HS Code: 8419500090

Port: Guangzhou

Payment Type: T/T,L/C

Incoterm: FOB,CFR,CIF,EXW,DDU,Express Delivery

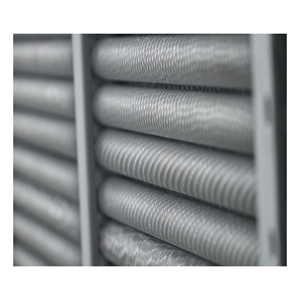

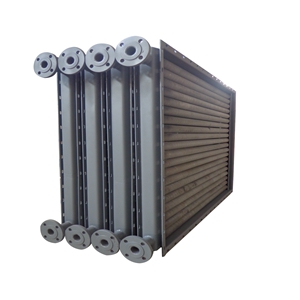

Copper Fin Fan Cooler with Zinc Coating is also called Fin Fan Exchanger or Plate Fin Type Heat Exchanger. The air radiator is a main device from the heat exchangers family which apply a cold medium and a heat medium for air cooling or heating. It can heat air if fed with high-temperature water, steam, heat transfer oil, and cool air if fed with chilled water.

In this regard, our Fin Fan Cooler is extensively used in warm-air heating, air-conditioning, cooling, condensing, dehumidifying and drying and finds its way into leading industries such as light industry, architecture, chemical industry, machinery, textile, printing and dyeing, electronics, food, pharmaceutical industry, metallurgy, wood, plastics, rubber, etc.

Selection principles, steel standards, thermal treatment states and permissible stress values of the materials of the pressure parts should be subject to requirements of the GB150. The pressure parts used in inflammable, fatal or toxic operating environments should be made of cast iron.

The common parent tube materials include carbon steel Q235B, 20#, 304, 316, copper tube, etc.

The common fin materials include carbon steel, 304, 316, aluminum, etc.

| Parts of the Plate Fin Type Heat Exchanger | Material |

| Connecting plate | Carbon steel Q235B, 304, 316 |

| Tube plate | Carbon steel Q235B, 304, 316 |

| Header tank (header pipe) | Carbon steel Q235B, 304, 316 |

| Interface | Carbon steel Q235B, 304, 316 |

1. Keep the cooling surface of the Cooler clean by blowing with compressed air or flushing with running water.

2. When the Fin Fan Exchanger uses hot water as the heating medium, the hot water should be softened to reduce scale.

3. After the Plate Fin Type Heat Exchanger has served for two to three years, clean its cavity with a chemical method to remove the scale in it.

4. When the Fin Fan Cooler is not running in summer, fully fill its cavity with water to reduce the generation of rust in it.

5. If fins of the Fin Fan Exchanger are inclined because of collision, straighten it manually to avoid a larger ventilation resistance.

6. Frequently inspect the pipe connection quality, part sealing and regulating device flexibility of the Exchanger and, if any problem is found, repair it promptly.

7. To prolong life of the Finned Tube Heat Exchanger, remove the blocking matters in its pipe with clean water or a chemical method after it has normally served for about three moths to avoid more serious local corrosion and improve its service efficiency.

8. When the Plate Fin Type Heat Exchanger is not used in winter, drain all the water in it to avoid Finned Tube cracking due to freezing.

1. What is the advantages of Finned Tube Heat Exchanger like Fin Fan Cooler?

a.High heat transfer performance and low contact thermal resistance;

b. The contact area between the fin and the tube is large,and the joint is tight and reliable;

c. Good corrosion resistance and stable long-term service performance;

d.The fin has good rigidity and is not easy to deform.

2. How many types of fins do you make as part of the Plate Fin Type Heat Exchanger?

We have been manufacturing Extruded Finned Tube, Spiral Wound Finned Tube, Embedded Finned Tube and more with copper and aluminuim as the main materials.

Product Categories : Air Heat Exchanger > Finned Tube Heat Exchanger

Home > Products > Air Heat Exchanger > Finned Tube Heat Exchanger > Copper Fin Fan Cooler with Zinc Coating

Send Inquiry

Ms. Abby

Tel:+86-020-82453507

Fax:

Mobile Phone:+8613662249479

Email:jmheatexchanger@163.com

Address:No.73, Bigang Road, Nangang Street, Huangpu District, , Guangzhou, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.