Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Jiema

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Place Of Origin: China

Use: Heater Parts

Certification: Ce

Warranty Period: 1 Year

Service System: Video Technical Support, Online Support

Size: Customized

Material: Carbon steel, Stainless steel

Usage: Cooling, Heating

Connection Method: Welding

Diameter: 18mm to 2800mm

Standard: GB, ASME, ANSI, EN

Grade: Class 1

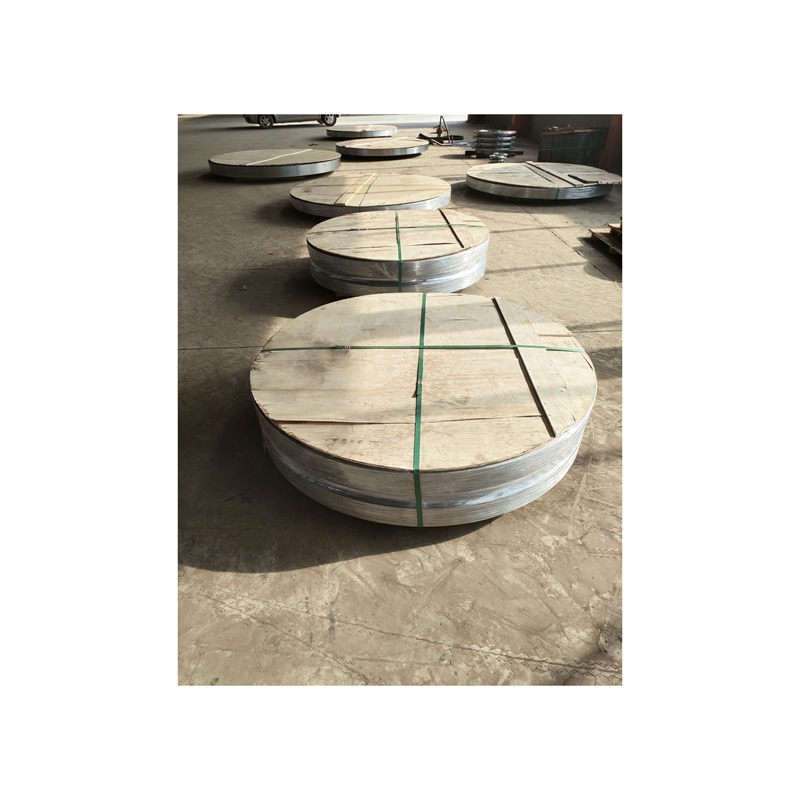

Packaging: Plywood box or pallet

Productivity: 10000 pcs per month

Transportation: Ocean,Land,Air,Express

Place of Origin: Guangzhou, China

Supply Ability: 10000 pcs per month

Certificate: ISO 9001:2015 CE

HS Code: 8419909000

Port: Guangzhou

Payment Type: T/T,L/C

Incoterm: FOB,Express Delivery,CFR,CIF,EXW,DDU

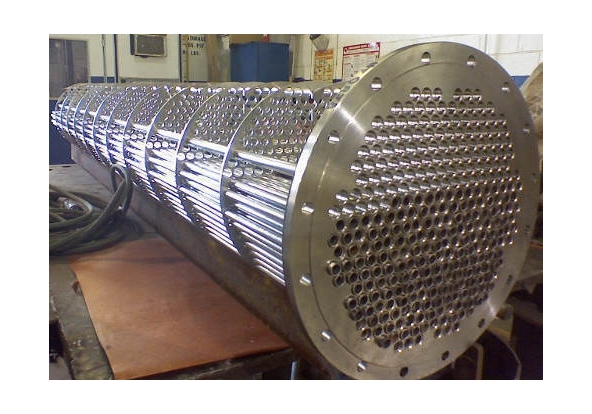

Fixed tube sheets can be used in fixed shell and tube heat exchangers, U-tube heat exchangers or floating head shell and tube heat exchangers. Among them, the Floating Head Heat Exchanger needs a floating Tube Sheet and a fixed tube sheet, and the other two shell and tube heat exchangers only need a fixed tube sheet.

In the calculation of the fixed tube sheet, the axial stress of the shell, the axial stress of the heat exchange tube, and the pull-off force q between the heat exchange tube and the tube sheet are calculated according to various working conditions with temperature difference. When the strength (or stability) conditions are met, expansion joints are required. In the calculation of the strength of the fixed tube sheet, when the thickness of the tube sheet is determined and no expansion joints are provided, sometimes the strength of the tube sheet is not enough. After the expansion joints are provided, the thickness of the tube sheet may meet the requirements. At this time, expansion joints can also be set to reduce the thickness of the tube sheet, but it should be determined from a comprehensive evaluation of material consumption, manufacturing difficulty, safety and economic effects.

U-shaped expansion joints are commonly used in fixed tube sheet heat exchangers, which have the advantages of compact and simple structure, good compensation, and low price.

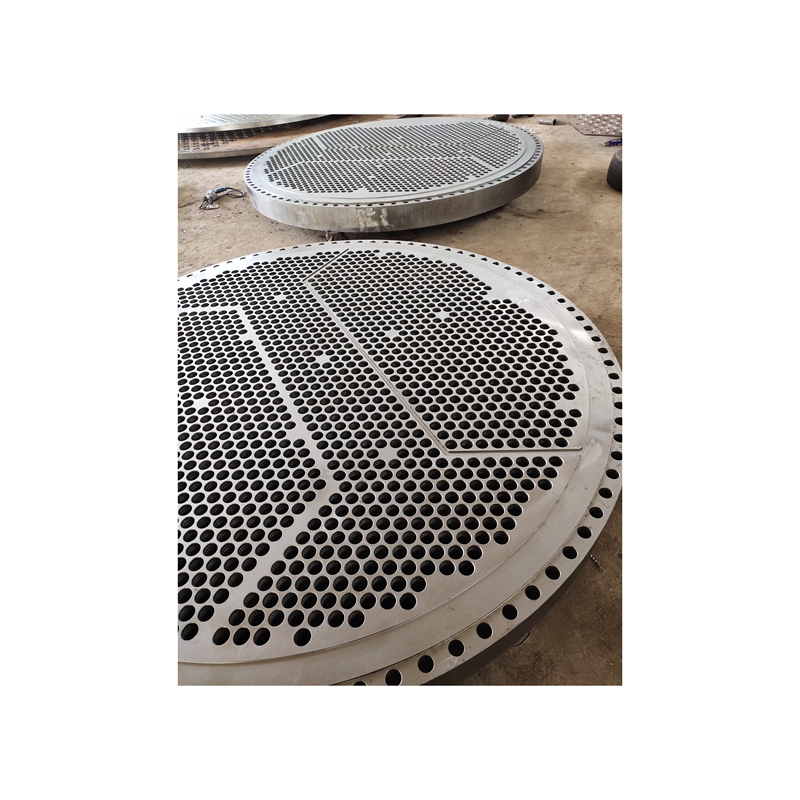

With the large-scale chemical equipment and power stations, the diameter of the tube sheet is also becoming larger and larger, and the tube sheet with a diameter of 4m-5m is very common. Large-scale tube sheets are characterized by a large number of tube holes, dense, small aperture, deep, and high requirements for precision and finish.

Standard:

ANSI B16.5/ B16.47/ B16.36/ API605, 6A, 6B/ MSS SP44/ AWWA C207

DIN 2527/ 2528/ 2561/ 2565/ 2566/ 2573/ 2576/ 2627/ 2630/ 86029/ 86030 etc.

BS 4504 PN16/PN40, BS10 TABLE E/TABLE D

JIS/KS 5K, 10K, 16K, 20K, 30K

UNI 2253/2254/2276-2278/2281-2284/6083/6084/6089-6093

GOST 12820/12821

Material Available:

Carbon steel (ASTM A105 A350LF2 LF3 A694 A36 Q235 A3 20# 45# 20Mn 16Mn Q345 etc.);

Stainless steel (SS316, SS304, SS316L, SS304L, SS321 SS317 F51 F53 316Ti etc.);

Alloy steel (A182F5 A182F11 F22 15CrMo 30CrMo 35CrMo 40CrMO 42CrMo 4130 4140 etc.)

PN: 1.0--------58.0

American Series: CLASS 150, CLASS 300, CLASS 400, CLASS 600, CLASS 900, CLASS 1500, CLASS 2500

European Series: PN 2.5, PN 6, PN 10, PN 16, PN 25, PN 40, PN 63, PN 100, PN 160, PN 250, PN 320, PN 400

The package of tube sheet ban be wooden pallet and cover, and plastic strip for fixing.

About Us

About Us

Guangdong Jiema Energy Saving Technology Co., Ltd. (hereinafter referred as Jiema) used to be called Guangzhou Jiema Heat Exchanger Co.,Ltd. As a professional manufacturer of energy equipment, our product range is not only including heat exchanger, Water Chiller and Cooling Tower, but also including the accessories of Seamless Tube, Flange, pipe fittings and so on. Our production line of accessories can meet our own demand as well as our customer's inquiry. We offer competitive price and stable quality for all of our product range.

1. How to judge the quality of tube sheet?

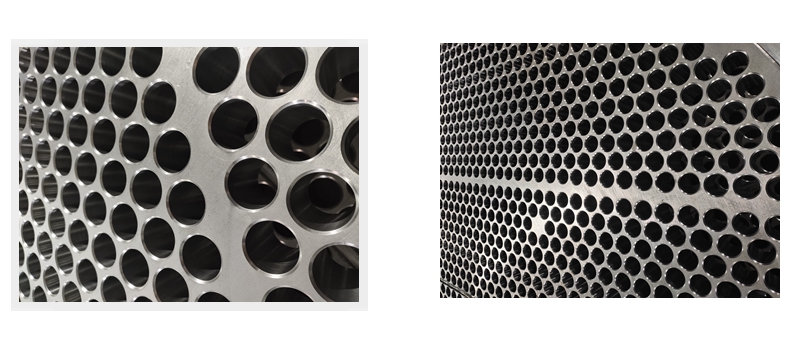

In the inspection process of the tube sheet, the main inspection indicators are the hole position, the hole diameter tolerance, the smoothness in the hole, the presence or absence of burrs, the position of the groove, etc. For the double tube sheet, more attention is paid to the hole position during the inspection process. Hole fit is very important. Generally, it can be guaranteed with a CNC drilling machine. Compared with thick plates, the verticality of holes above 300mm is very important. These thick plates with large diameters require more precise tools and equipment, and the application of special gantry machining centers will become more and more common.

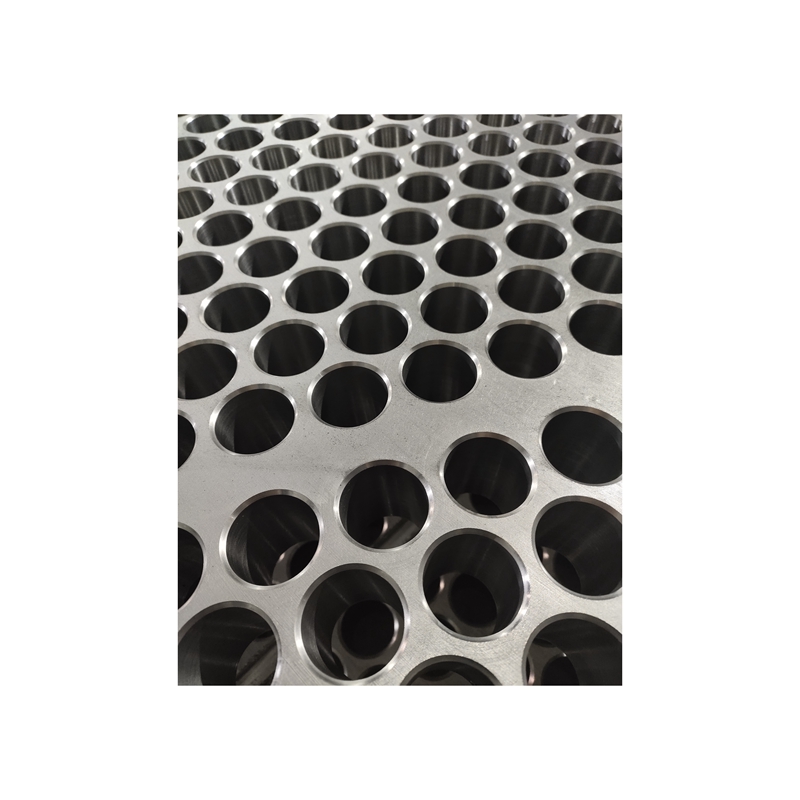

2. What's the method to fix tube on the tube sheet?

One method is by tube to tubesheet welding. Another method is by expandiong tubes, but this way has higher requirement of precision for both tube and tube sheet.

Product Categories : Heat Exchanger Parts > Tube Sheet

Home > Products > Heat Exchanger Parts > Tube Sheet > Fixed Tube Sheet for Heat Exchanger

Send Inquiry

Ms. Abby

Tel:+86-020-82453507

Fax:

Mobile Phone:+8613662249479

Email:jmheatexchanger@163.com

Address:No.73, Bigang Road, Nangang Street, Huangpu District, , Guangzhou, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.