Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: JIEMA

Design Temp.: 120 ℃

Design Pres,: 1.0 MPa

Packaging: plywood

Productivity: 10000000 sets

Transportation: Ocean,Land,Air,Express

Place of Origin: Guangzhou, China

Supply Ability: 1000000 sets

Certificate: ISO/CE

Port: Guangzhou

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

The project has a construction area of 1.56 million square meters, and four 29 MW gas-fired hot water boilers are installed. The heat network return water temperature is 45~50℃ and the water supply temperature is 75~100℃.

A high-efficiency flue gas Air Heat Exchanger is added to the exhaust of the four gas boilers and a BDZ600-R1 direct-fired heat pump is added to recover flue gas heat. After the completion of the renovation, the total energy saving of the heat pump unit is 18,000 GJ in 97 days of operation, accounting for about 6.9% of the total heat supply. Based on one full heating season, the heat recovery will reach 23,000 GJ, which is equivalent to saving 785 tons of standard coal/year and reducing 2176.4 tons of CO2/year.

Flue gas heat exchanger, Twisted Tube Heat Exchanger, is a kind of waste heat recovery equipment, which is simply a heat exchanger for our flue gas to achieve the heat change of two media. The flue gas will generally transfer heat with water, air, heat transfer oil or its substances that can absorb heat from hot flue gas because of the presence of temperature difference.

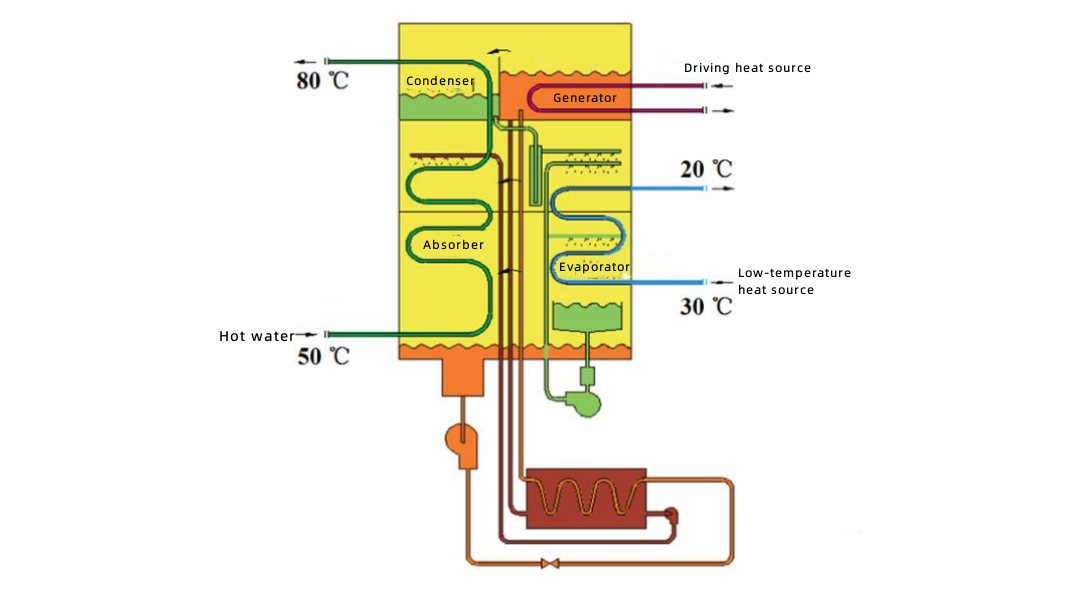

The absorption lithium bromide heat pump is driven by thermal energy (gas, steam or hot water, etc.) to generate low temperature water and send it to the flue gas heat exchanger. The low temperature water passes through the flue gas heat exchanger to recover waste heat from the exhaust of large boilers, and the recovered heat is sent to the heat network, which can effectively recover low-grade waste heat from the exhaust of boilers.

Product Categories : Air Heat Exchanger > Twisted Tube Heat Exchanger

Home > Products > Air Heat Exchanger > Twisted Tube Heat Exchanger > Gas Heat Recovery Heat Exchanger

Send Inquiry

Ms. Abby

Tel:+86-020-82453507

Fax:

Mobile Phone:+8613662249479

Email:jmheatexchanger@163.com

Address:No.73, Bigang Road, Nangang Street, Huangpu District, , Guangzhou, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.