Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: Jiema

Material: Carbon steel, Stainless steel

Usage: Cooling, Heating

Packaging: Plywood box

Productivity: 1000 pcs per month

Transportation: Land,Ocean,Air,Express

Place of Origin: Guangzhou

Supply Ability: 1000 pcs per month

Certificate: ISO 9001:2015 CE

HS Code: 8419500090

Port: Guangzhou

Payment Type: T/T,L/C

Incoterm: FOB,Express Delivery,CFR,CIF,EXW,DDU

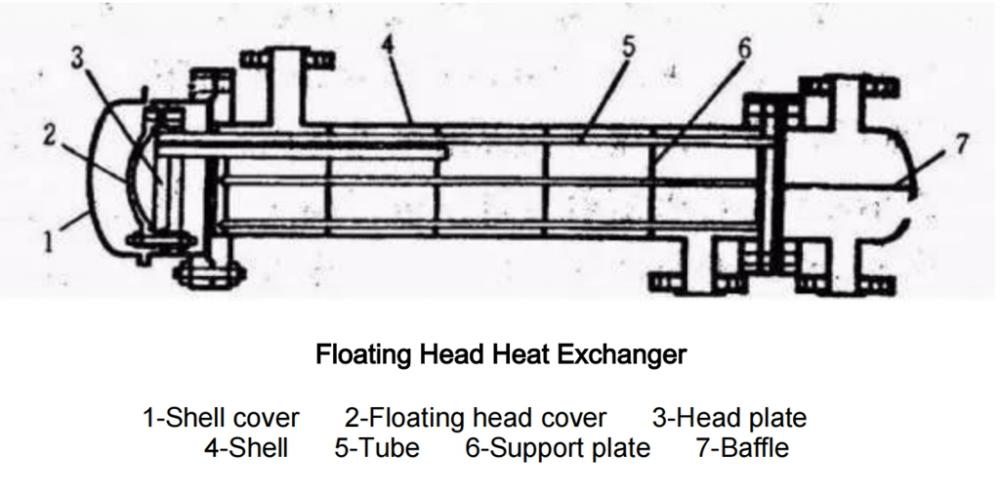

Jiema Floating Head Exchanger for Juice/Beverage Heating, also known as Floating Tubesheet Heat Exchanger, is completed by connecting head plates, shell, tube bundles, mounting Flange and more. For one fluid, we lead it through the tubes that are connected with the head plates, with several channels available in line with different operation conditions. For the other, it will be into the shell and uniformly distributed over the outer tube but inside the shell.

Considering various technical requirements from our customers, our Split Ring Floating Head Heat Exchanger then puts a few baffles in a bid to increase turbulence of the shell side fluid and make more heat exchange happen. Except for that, the heat transfer master himself, tube bundles, ranges from brass tube, copper-Finned Tube to steel tube, with an attempt to realize heating and cooling of different working fluids.

1. Hydrostatic test pressure would be 1.5 times higher than the operating pressure with the duration of 10 minutes; (Steam:+0.3MPa;Hot water:+0.4MPa)

2. Space shall be left for future removal of the tube bundles; estimated distance between the floating head and the wall/roof of the room should be no less than the total length of the equipment;

3. Relevant valves and digital instruments shall be installed at a height that is best suitable for operation and observation;

4. Vertical clearance between the highest location of upper attachment(mostly safety valve) and the floor shall meet the installation requirements and not less than 0.2m.

Addressing to the principle of “Build a company under the guideline of integrity and achieve success on quality" and the ideology of “Constant development and continuous innovation", Guangdong Jiema Energy Saving Technology Co.,Ltd strives to provide products with stable performance at a relatively low price for users.

1. Can Split Ring Floating Head Heat Exchanger parts be removed from the equipment?

Yes, they can. Our Floating Head Heat Exchanger, can be removed from the floating head and be cleaned.To name just a few, there is Floating Head Exchanger, Floating Tubesheet Heat Exchanger, Split Ring Floating Head Heat Exchanger and so much more.

2. Why there is corrosion of my Floating Head Exchanger?

It could be the corrosive fluid at the tube side. The fluid’s concentration, temperature, PH value as well as velocity would largely determine the degree of the corrosion. Therefore, please pay attention to these details if trying to prevent corrosion. Contact us for more prevention details.

Product Categories : Shell And Tube Heat Exchanger > Floating Head Heat Exchanger

Home > Products > Shell And Tube Heat Exchanger > Floating Head Heat Exchanger > Floating Head Exchanger for Juice Beverage Heating

Send Inquiry

Ms. Abby

Tel:+86-020-82453507

Fax:

Mobile Phone:+8613662249479

Email:jmheatexchanger@163.com

Address:No.73, Bigang Road, Nangang Street, Huangpu District, , Guangzhou, Guangdong

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.