Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: JIEMA

Packaging: Plywood

Productivity: 10000 sets

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 100000 sets

Certificate: ISO

Port: Guangzhou

Payment Type: L/C,T/T

Incoterm: CFR,FOB,CIF,EXW,DDU

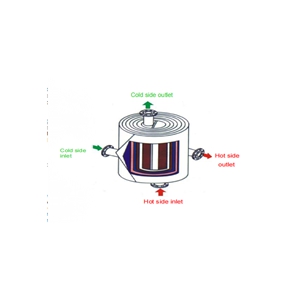

The role of spiral plate heat exchangers in oil refining systems includes thermal energy recovery, temperature control, phase change treatment and prevention of scaling and clogging. It plays an important role in improving energy utilization efficiency and ensuring the stability and efficiency of the oil refining process.

A large amount of thermal energy is generated in the oil refining process, and the Spiral Plate Heat Exchanger can achieve thermal energy recovery and reuse by transferring thermal energy from the high-temperature fluid to the low-temperature fluid. . This helps to improve energy efficiency and reduce energy consumption and costs.

In the oil refining process, different processes require different temperature conditions. The Spiral plate heat exchanger can achieve precise fluid temperature control by adjusting the heat exchange between the fluids. This is very important to ensure the stability and efficiency of the oil refining process.

In the oil refining process, the phase change process between liquid and gas may be involved, such as distillation, condensation, etc. The spiral Plate Heat Exchanger can achieve effective treatment and control of the phase change process by providing a sufficient heat exchange area and an efficient heat transfer effect.

Oil contains various impurities and sediments, which are easy to form and clog inside the heat exchanger. The design of the spiral plate heat exchanger can reduce the risk of fouling and blockage, and improve system stability and reliability.

Product Categories : Spiral Plate Heat Exchanger

Home > Products > Spiral Plate Heat Exchanger > Spiral Heat Exchanger Oil System

Send Inquiry

Ms. Abby

Tel:+86-020-82453507

Fax:

Mobile Phone:+8613662249479

Email:jmheatexchanger@163.com

Address:No.73, Bigang Road, Nangang Street, Huangpu District, , Guangzhou, Guangdong

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.